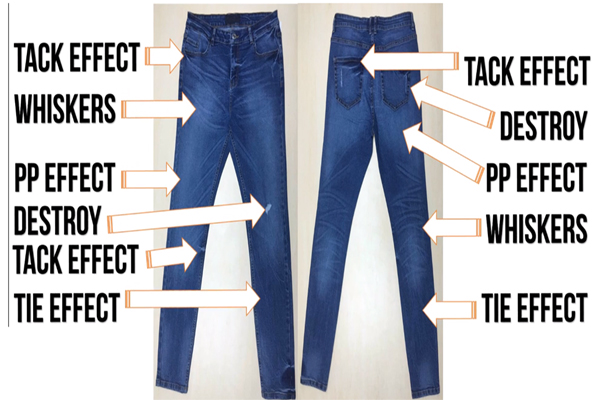

Now we are leaving in the fashionable era. Everyone wants to wear a new and fashionable garment. Everyone wants to present something different from others. Garments washing is a technology which applied to change the Design, Style, appearance and make comfortable of the garments. If you are looking at different types of jeans in the market but the same style. There is Some Light some are Deep some tack effect some are destroyed. This all is actually a washing effect. Different types of wash effect are available in the garments industry. But we don’t know about the effect name also.

Ok, let’s go to know about some Wash effect name. There are Whiskers, Tack Effect, pp effect, Destroy Effect, Tie Effect, etc.

However, different types of garment need to different wash and Different types of Wash depend on Different Fabric nature.

Types of Garments Wash:

Table of Contents

Garments wash basically depend on garments Fabric. You can’t apply on all fabric within one Wash.

Denim Fabric:

Day to day denim wash is very popular according to the faction and appearance. Some of the denim wash name as below.

- Rinse Wash

- Enzyme Wash

- Stone Wash

- Acid Wash

- Tinting

- Net Bleach

- Milk Wash

- Cold Pigment Wash

Knit Fabric Wash:

The name of the washing system that applied for knit fabric.

- Stone Enzyme wash

- Rubber Ball Wash

- Hot Wash

- Garment Wash

- Tie Wash

- Deep Dye

- PP Spray

Woven Fabric wash:

Different types of washing system that applied for the Woven Fabric Garments.

- Rinse Wash

- Resin Wash

- Softener silicon wash

- Medium Stone enzyme wash

- Bleaching wash

- Towel Bleach Wash

- Rubber Ball Wash

Types of garments washing machine:

In garments industry washing plant, need to use different types of garments washing machine for different purposes.

Different types of Garments washing machine used in industrial washing plant for bulk production. These are mentioned in the below list:

- Side Loading Washing Machine.

- Stone Washing Machine.

- Semi-automatic washing machine.

- Front Loading Washing Machine.

- Fully automatic machine.

- Top loading washing machine.

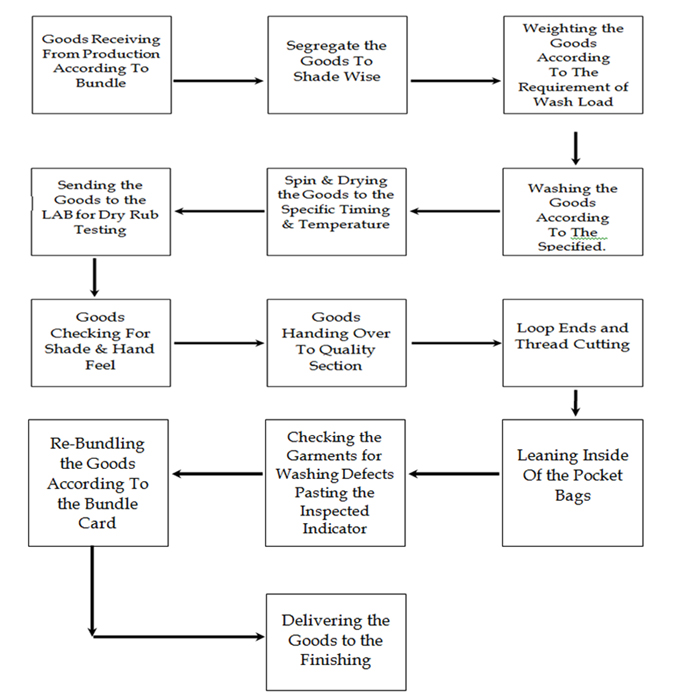

Pre Washing Process:

Washing Plant the work starts with a bundle ticket. Which is carried through all process like a shadow of the garments From store department Who actually receive all garments from sewing floors. After Receiving garment need to hand over to the washing Department with the bundle ticket provided to clarify the size, shade, and quality of the garment.

Moreover, you can follow another system, which clarifies the respective duty of the engaged worker in the washing plant by Loader Ticket. Actually, by loader report, it clarifies the things are done and kept accordingly like size-wise and shade wise so that after all sorts of washing it can be resorted ut according to the bundle ticket and keeping all sorts of mistake under control and this also to be furnished by this unique system. Below the complete flow of work of garments washing plant is related in a simple and precise manner.

The procedure of Garments Washing:

As I have told with the bundle ticket the washing plant activities getting started. From this store, people sorted out the bundle by shading and handed over the same to the washing people. Washing guy receiving the same started to wash according to the washing instruction provided by the supervisor who will determine the same for proper washing as per the instruction is given by the merchandiser who is simply following the buyer’s instruction or Samples.

Generally, it is done with time-limit as per fixation on the chemical or enzyme or ordinary detergent wash with the help of some machine.

For Example, your Factory has 35 washing machine for bulk production, 51 dryer machine, and 15 hydro-dryer machines to squeeze the water and chemicals from the garments.

Then Ensure the results are expected way or else provide with instruction to do the same washing procedure again to retain to the original swatch.

It has to be ensured which is given by the supervisor for the operator’s work to be guided all through the washing process.

After that a lot of processes to be followed according to buyers instruction.

Precisely to replicate the buyer’s sample out and out, like sand-blasting, melding the hem with strong brushing, or tearing somewhat, stone washing and many more. Furthermore, in every process, there needs a quality checking that ensures the end product is OK with quality and ready for further maturation.

The Procedure Of chemical and FOB:

Washing plant must use Teflon chemical actually this Comical is very expensive and can make an impression of water repellence onto the fabric after being naturalized of the same. Here treatment of the fabric along with washing is taken care of and lots of precaution measures are simultaneously taken into account so that after wash loss is controlled in the end.

After all sort of washing process it takes rigorous quality checking as final to get back the whole lot according to the bundle ticket provided by the store department so that washing plant can offer the same garment with washing touch/impression back to the store for finishing accessories to be attached for final shipment on time meeting the shipping window for FOB to harness.

How to Reduce Wash Cost:

Here some innovative process has been invented to reduce after-wash loss like fabric pen has been used to get the actual impression of the washing. Besides the painting section is also introduced to get the loss under control from the second’s garments.

Apart from that, this is the washing plant that well managed as ETP has been installed here since its inception to get back the green and sustainable environment free from chemicals injurious to nature.

Here the chemical room is managed properly so that every paper relating care instruction and all is managed for any kind of compliance- audit to follow any time round the clock.

PPE is maintained properly and every staff accustomed to impart their respective job keeping the code of conduct of the work, supervisors are always maintaining the same round the clock as Garments Washing Plant is working for 24 hours, thus they will help to earn the foreign currency.

Garments Washing Process flow chart :

The Process of Washing-Plant functions is shown in the following figure :