In the current era, many companies have reaped the benefits of using robots. But, in the textile industry, robots help to minimize efforts in various processes. As a result, robotics makes the production phase smooth than ever before. So, let’s check how robots can help to improve textile manufacturing.

#1 Robotics help to handle bales inside a blow room

Table of Contents

In the textile industry, workers often have to store the bales in a better way. Hence, when the conveyor moves the bales to the loading station, the robot picks up the bales. These are later stored with specific numbers. Posting selecting the bale for processing, the robots help to move them. Before moving ahead, the robot selects the bales on a ‘first in, first out’ basis. Moreover, once the workers program the robots, they can also sort the bales.

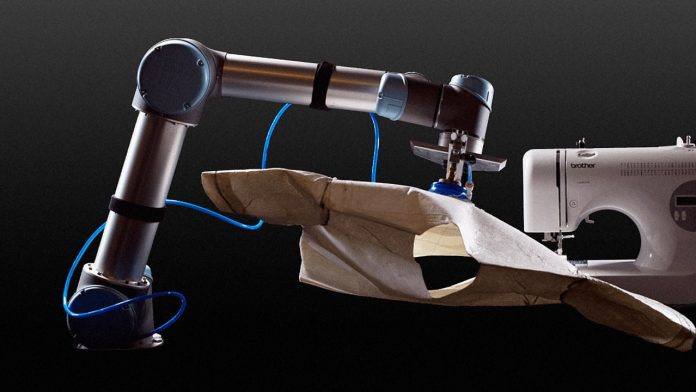

#2 Robotics help in handling fabrics

When sewing clothes is the prime concern, robots can be helpful for sewing the fabric. While the robots handle the fabric, they can stitch apparel completely. Moreover, the workers can set the robots for a particular fashion trend in mind. If the workers observe a change in the style, they only have to program the robots once again. With the help of a lock stitch machine, workers can also control the sewing process with ease. Way ahead, companies can think about laser welding to join two pieces of fabric.

#3 Companies use robots for laser cutting

When the workers have to cut the fabric with great care, they can think about using robots. With the best technology, the computer can later control the laser cutting system. The industry can use such systems for cutting heavy textile materials. Once the system is in place, it can help to expedite mass production on the floor. Eventually, laser cutting can help to cut the fabric with great precision. For testing the fabric under certain conditions, robots can stress test garments effectively. These robots will help you conduct tests without anybody’s intervention.

#4 Workers use robots for 3D fiber printing

With the advent of technology, textile industries use robots for 3D printing. Synonymous to usual 3D printing, workers use robots, particularly for protective uniforms. As soon as the robot is set, it guides the fabric into the desired structure. Later, the polymer becomes hard and sets in at different places. In the end, robots are bound to do a good job than experienced workers.

#5 Robots help to pick clothes at the warehouse

Once the workers set up robots at the warehouse, they can pick the clothes from one location to the other. In those instances, it can reduce manual tasks to a great extent. The workers will no longer have to spend time walking from one place to the other. With this in mind, you will encounter an increased demand for warehouse robotics. The company can also use continuous path control robots to perform many operations.

Bottom Line

To sum everything up, you will come across many applications of robots. The robots can not only handle fabrics but also handle bales till they reach the loading station. To speed up mass production, companies also use robots to cut textile materials. They can also help the company to carry out 3D fiber printing in the best way. If the warehouse is spread across a large area, then robots can help to pick garments from one place to the other.