The finishing department in garment industry is one of the most important departments. The final shipment of the products greatly depends on the finishing department. The desired quality standard of the products also depends on this department. So the smoother and efficient operation of the finishing department is very important. Different activities of the Finishing Department can be summarized as-

- Receives garments from production floor & Washing plant.

- Sucking all garments by Sucker machine.

- Pressing by Trouser Topper, Legger and Topper Machine.

- Taking the measurement.

- Accessories attaching.

- Quality checking.

- Storing in the Finished Goods Store.

- Inspection by the Audit Team.

- Final shipment.

Finishing department in garment industry: Process:-

Table of Contents

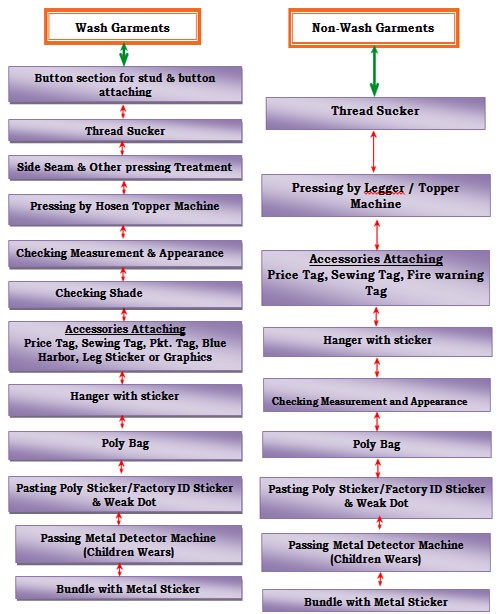

The garments are received along with a bundle card where the details about the garment are written, like style, size, quantity etc. If the garments need to be washed then the garments send to the Washing Plant along with the bundle card. The finishing department usually received two types of garments –

- Wash garments: Wash garments are received from the washing plant after wash and followed by some other processes in the finishing department in

garment industry. - Non-wash Garments: Non-wash Garments directly comes from the production line to the finishing department.

Sucking:

All the received garments send to this section and the garments are passed through the sucker machine. The main purpose is to take out any cut thread and any other unnecessary dust.

Pressing:

There are different pressing machines are available for this purpose. These machines are-

- Trouser topper – These machines are used to press the washed garments.

- Legger – These machines are used to press the non-wash garments.

- Topper – These machines are also used for non-wash garments.

- Iron table – the Iron table is used to ironing the garments.

Taking the Measurement:

After receiving the garments from the production line or Washing plant, measurement is taken of all the garments.

Quality Checking:

All the complete garments have to be passed by the quality checker. The steps involved are Measurement checking, Shade checking and Checks for any defects and spots uneven.

Followings are the accessories that are attached especially on DENIM TROUSER –

- Leg Sticker

- Fire warning

- Metal Sticker

- Pocket Tag

Here first the back pocket sticker is attached and then price tags are labeled. The back pocket sticker tells about the garment. The contents of the price tag are price, size, style, color etc.

Packing:

In this step, all the garments are packed in a poly bag. Two denim trousers are packed in one polybag. Then the poly stickers are pasted on the bag.

Storing:

The packed garments are then sent to the finished goods store for the final shipment. All the garments have to be passed through a METAL DETECTOR before storing for the final shipment. Especially all children wear or school wear must be passed through the metal detector. This is because of safety and our company is practicing totally metal free environment in the factory.

Inspection by the Audit Team:

The inspection is done in two steps.

- Style wise: samples are taken from the same style at a time and checks. The resultant report is given to the production and quality manager. As per the reports they take the corrective action if necessary.

Daily basis: Daily pieces garments are picked randomly per style and inspects. Than reports to

the production and quality manager.

Packaging:

Packaging is the last process of the finishing department in the garment industry. Same style, color, and shade packed in the same Cartoon. Also, same size garments contain in the same cartoon.

Cartoon Marking:

The following markings are mentioned in a cartoon.

- Cartoon number

- Style

- Size

- Color

- Quantity

- Net weight

- Gross weight

- Measurement

Final Shipment:

Final shipment depends on the buyer’s requirements. It can be of two types-

- Hanging in the container.

- Cartoon wise in the container.