The maintenance department is enhanced with various professionals who work for maintaining the continuous production system and keep machinery in working condition. Maintenance Department is one of the most important parts of the factory. The maintenance department is mainly responsible to look after the machines and other production equipment in proper working condition and take corrective action against any environmental pollution. A good Maintenance Different types of maintenance techniques apply in RMG Sector.

In a factory, should keep one Maintenance Manager and three Assistance Maintenance (Manager).

One Assistance Manager is for the civil section and another two Assistance Manager are for the mechanical section.

OBJECTIVES:

Table of Contents

- To maintain smoother production.

- To overcome the machinery and production system related problems.

- Reengineering efficiently to reduce pollution.

The function of Maintenance Department :

- Inspection of sewing machines and other machinery in the factory, repairing and up gradation.

- Maintaining and ensuring continuous power supply in the factory.

- Maintaining proper water supply, compressors, boilers etc.

- Planning, design and implement any kind of expansion of the factory.

- Supply purified water for factory using and washing plant.

- Maintain WHO standard PH value for ETP (Effluent Treatment Plant).

- Purchase of new machinery.

- Issuing of different spare parts and accessories according to the production requirement.

- Housekeeping.

- New constructions, paintings, and furnishing of the factory.

Maintenance Department supervising and controlling the activities by the head of the maintenancedepartment. Mechanical & Electrical section, Civil section, Raw Water Treatment Plant (RWTP) and Maintenance Store are the four different sectors of this department.

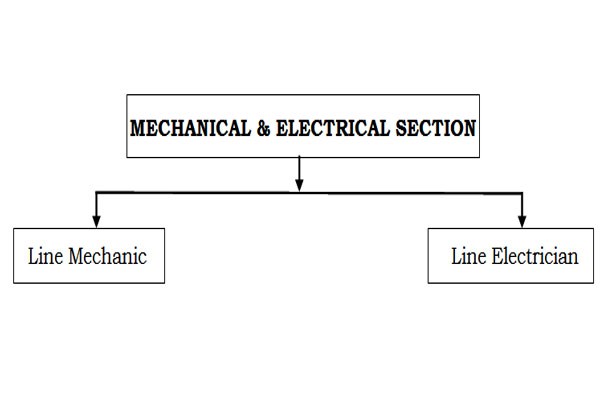

1. MECHANICAL & ELECTRICAL SECTION

- Maintaining mechanics in the section to assist the production to run smoothly with minimum breakdown time of machinery.

- Maintaining the water plant, compressors, air conditioning systems, and boiler are the most important activities of this section.

This area of maintenance department deals with different activities given below in figure:

Boiler – There are two boilers in perform for the whole factory to supply steam outputs, which are basically used for different types of steam ironing and for other machines respectively.

Compressors – There are six compressors in the factory. These are used to operate different machines in the washing plant and different pressings and other machinery in the production.

Generators – There are three standby Generators are available in the factory as back up for PDB power failure.

2. CIVIL SECTION

The activities of this section to monitor the activities of Carpenter, Plumber, Labors and House Keepers. There are three functions of this MNT section-

- New Constructions.

- Maintaining the factory condition.

- Making new furniture and doing repair works.

- Maintaining the water supply and drainage lines without a problem.

3. RAW WATER TREATMENT PLANT (RWTP)

RWTP (RAW WATER TREATMENT PLANT) makes supplied water and Self Tube-well water purified for factory use. ETP (Effluent Treatment Plant) generates from washing plant is separated to make treated water before releasing it to the drain. This process is doing according to the rules and regulations of the World Health Organization (WHO).

4. MAINTENANCE STORE

The MNT Store is responsible for looking after the spare parts and maintains the records of the maintenance department. The store of maintenance department issues different spare parts, needle and keep the records.

The basic purposes of this store are:-

- Issuing of spare parts and needle.

- Updating daily stock records.

Recording of attendance and overtime in a maintenance department software System.

Home Applances and Home Decoration is need of every home. Home is a good place to live in with quality branded home applainces.