There was a time when laser cutting technology was limited to heavy industries. It increased productivity and efficiency day by day. However, things have changed in today’s world. Now, you can see many small businesses and other professionals are using this technology.

You see, laser cutting is very beneficial, especially for small business owners. That’s the reason why it’s getting popular nowadays. Hence, many number plate businesses like Hex Number Plates are using this technology.

If you are ready to use laser cutting for your professional or personal purposes, you have to know the basics. In this case, we can help you out. That’s why we will share the types, methods, and other details of this technology.

Moreover, we will also share how you can use this technology to make number plates and customized number plates. So, make sure you read each point carefully. Let’s get started.

What is Laser Cutting?

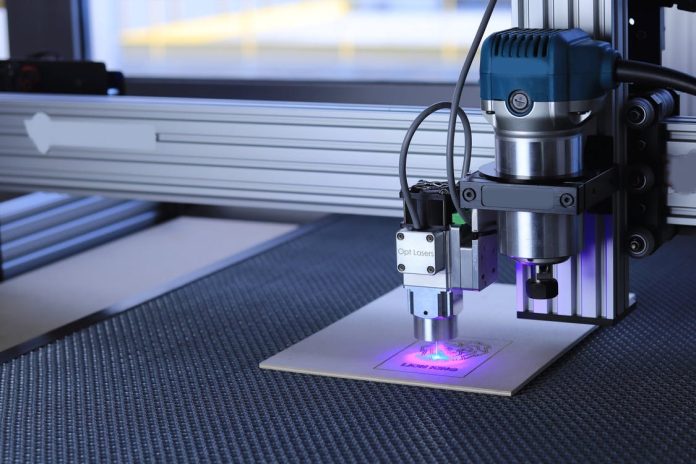

Before we dig deeper, you have to know the basics of laser cutting. Well, it’s a material cutting method. When someone is applying this technology, an intense and focused stream of light will cut through the metal.

Besides metals, this method is applicable for acrylics, wood, and paper. Well, laser cutting has several methods. And the optics are controlled by Computer Numerical Control which can drill small holes.

The first production of this technology was in 1965. At that time, it was used for cutting diamond dies. Later, they started using this method for several things. Now, laser cutting has become an essential part of heavy and small industries.

Types of Laser Cutting

You can say there are three types of laser cutting; cutting, boring, and engraving. The best thing is these types of laser cutting can be used for welding. CO2 can be used in gas mix. And it’s very popular right now.

There’s a new technique called the RF method (radio frequency energy). When you use this method, it will avoid electrode erosion problems. On the other hand, you can use different techniques to cool external optics and laser generators. Hence, you can also use water as a coolant.

How Does Laser Cutting Work?

So, how does laser cutting work? If this question is bugging you, let’s find out how it actually works. As we noted before, laser cutting uses a high power laser that is directed through computer numerical control.

The process has a motion control system that can help it follow CNC. So, the high power laser can be burned, melted, and vaporized by a jet of gas. Another piercing process can be used for the edge of the material.

Methods of Laser Cutting

Now, you know how this technology works. Well, there are several methods of laser cutting. If you want to use this technique for your business, you have to learn about these methods. In the following list, we will share the five best methods of laser cutting. Let’s find out:

- Sublimating

Sublimating is also known as vaporizing. Well, it’s a phrase that changes a solid state to a gaseous state. For example, you can take how dry ice becomes vapor. It happens when the material absorbs high energy in a short time. You see, this method is ideal for cutting wood, paper, plastic, and foam.

- Melting

Melting is another popular laser cutting technology. Well, it takes less energy compared to sublimating. The laser beams start heating with the material. And it starts the melting process. As this process doesn’t require a lot of energy, it’s good to cut active metals such as aluminum alloys, titanium, and stainless steel.

- Reactive Laser Cutting

Besides melting and sublimating, reactive laser cutting is also getting popular nowadays. In this case, a reactive gas will start processing and generate more heat. It will start melting materials.

The reaction between oxygen and the metal releases heat. And this heat helps melt the material. As we noted before, this method is useful for cutting thick carbon steels, and other oxidized metals.

- Thermal Stress Fracture

In thermal stress fracture, you have to use a kerf at the depth of the metal thickness. When we pass the laser beam, the area creates thermal stresses. In some cases, you can use coolants to generate thermal stress. It’s still a new method. That’s why the use of thermal stress fracture is still unknown.

- Stealth Dicing

Stealth dicing is another useful laser cutting method. This method is very useful to cut semiconductor wafers and microelectromechanical systems. Here, you have to put the kerf in the internal point. However, it’s a dry-cutting process and can be very effective. The finishing is clean as well.

How to Use Laser Cutting to Make Number Plates

Many business owners are using laser cutting for various activities. In this case, number plating businesses can have benefited by using this technology. Moreover, many companies are also designing 4D or 3D laser cut number plates for cars.

Besides car number plates, you can also use this technology for general number plates. Hence, you can also design customized number plates. Laser cutting is more effective compared to other methods.

If you want to choose a custom number plate, there are several providers available. In this case, you have to choose the right company that has a top-notch team. On the other hand, if you are thinking that a custom number plate is illegal, you don’t have to worry about it.

The answer is no. It’s totally legal to use a custom number plate. In this case, you have to choose the right character and number plate size. The good thing is a good laser cutting company will help you out with these things.

Conclusion

As you can see, laser cutting technology can be a blessing for your business, especially when you are a beginner. Besides these things, this technology is also good for other activities. If you are ready to use this method, make sure you are clear about all steps. For more information, you can also contact an expert.