It is understood that a reader navigating through this site already knows what Computer Numerical Control (CNC) machining service is. Multiple manufacturing agencies have already adopted this technology (the global market extent was $70 billion in 2018). One anticipates that it will hit $111 billion by 2026 – a steep 6.8% growth. For the unversed, CNC machining implies a specialized manufacturing process wherein pre-dictated computer software controls the movement of factory machinery.

CNC manufacturing has reduced operating costs, negated manufacturing errors, and streamlined operations in a broader spectrum of machinery.

This curated piece of digital content will give you an idea – of how the CNC manufacturing process will impact the manufacturing industry in the upcoming years, what machine type is used, how environmentally sustainable it is, and what its future is. Let’s proceed –

How will the CNC manufacturing process impact the industry?

For the ones unaware – CNC machining service has already marked its footprints in the manufacturing industry. What is left to be seen is how it will impact the manufacturing industry in the future –

- Reduction in operating costs and maximizing efficiency levels

When the manufacturers are to deliver high-precision parts, they will have to use both computer-aided designing and manufacturing processes. As you might already know, both CAD and CAM have specific roles in prototyping. Considering that, when you are using a CNC machining service, the operating cost is automatically reduced. Additionally, it maximizes efficiency levels, and compared to manual labor, the detailing is better.

Result?

Given that the costs are reduced, and the precision is improved – automatically, the revenue levels reach higher metrics. Therefore – on the whole, this manufacturing system will positively impact the industry by reducing investments or capital input and increasing profits.

- Enhances quality with the automated technique

When using CNC machinery, be assured of getting just the ‘perfect diagonal cut’ as requested. As mentioned before, this runs on automated techniques, enhancing the quality levels. Compared to manual labor, the results are way more diverse than before.

Result?

When the production house gets an improved quality product via the automated technique, naturally, the profits will be higher. Also, when mass production happens, the output is more prominent, escalating the revenue levels.

- Amplifying the prototype and 3D modeling

Talking of the current production demands, prototyping, and 3D modeled products are the first-hand core material that is required in a production process. When using the CNC manufacturing process against manual labor, the resultant product will not only be free of manual errors but also be very precise and customer-oriented.

In fact, with CNC machinery, you can scan, engineer, and even reverse engineer various components to design a range of innovative products.

Result?

When toning down on manual labor, the production pace, especially those that use CNC plasma, speeds up the whole process. Therefore, the accurate prototypes will be curated, and this will have a direct effect on decision – making of the clients. In hindsight, the producer will look at the long-term benefit of this machining service.

- Greater Automation and Integration levels

Do you know what the biggest reason is for industries opting for CNC machining services? Its higher integration and automation levels. Undoubtedly, it is a complex process, but with multiple pieces of machinery integrated at certain levels, with CNC – one can streamline all of them into an automatic formation.

Result?

It is no secret that streamlining humans into a set format is complicated. They are no robots that can be timed. Also, efficiency levels vary from person to person. Therefore – the output is much lesser vis-a-vis a CNC machining service.

- Improved accuracy and safety levels

Lastly, CNC machinery enhances the production process’s accuracy levels, thereby increasing the security cover. The whole process is fed into the machine, it has its set of orders, and the task will be performed accordingly. They require no operator, and in the process, the errors are eliminated.

Result?

When the error rate lowers, the productivity rate heightens. Also, workplace accidents are reduced – thereby saving companies accidental cost.

What are the machine types used?

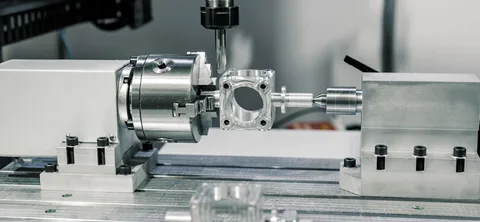

Technically speaking, the machines used in the CNC manufacturing industry vary. However, the 3-axis and 5-axis machine formats of CNC milling are the most used. Defining this a little more –

- 3-axis format: In this case, the machine is directed to work by removing the materials from the primary object with the use of cutting tools. It is a comparatively less flexible process and does not offer precise results.

- 5-axis format: This is directed to be more precise in terms of its working and its detail-oriented.

Is it environmentally sustainable?

As you have already noted the impact of this CNC manufacturing process in the industry and the types of machinery used – the next query you might have is, what is its ecological future? Apparently speaking, green businesses are looking for a manufacturing solution that will reduce carbon footprint levels. Hence, CNC manufacturing is a respite from this.

The biggest positive about this machinery is – its efficiency. Since they are electronically operated (use Computer Aided Design files for creating prototypes), they automatically lower the emissions rate. The process has become automated and improved the overall presentation.

Another crucial aspect of CNC machining is the presence of the Internet Of Things and non-human intervention, which results in broader collaboration – thereby creating better products. Going by the dictates of the Paris Agreement, the emission rates must tone down by 45% (2030 deadline) and to net zero (2050 deadline).

Therefore, CNC machining is a greener alternative to traditional manufacturing. Under such a state of affairs, the CNC manufacturing industry, ecologically speaking, has a very bright future.

What is the future of CNC manufacturing?

With industries looking forward to embracing automation, CNC machining service assists in alleviating costs and improving production levels. Also, in due course of time, areas within the CNC manufacturing process, such as 3D printing and precision mechanics, will automate the previously manual projects to the point of perfection.

Therefore, be assured that this manufacturing procedure will automatically escalate the productivity levels compared to the current standards. Having stated that, you need to choose an authentic service provider who will extend the same to you, thereby enhancing your work process.