One of the most essential parts of the Factory is apparels Store Department. Each and every factory must have a store where the raw materials are stored. The store Department is mainly responsible for receiving, keeping and issuing all kinds of Fabrics and other necessary accessories for production. All departments get their required things from Store. To maintain these, store department follows a regular work procedure. The basic functions of stores are defined as follows:-

Apparels Store Receiving Process:

Table of Contents

The procedure of incoming raw materials starts from the purchase order raised by the Merchandising Department. Then the commercial department informs Merchandising and Store about the arrival of raw materials to the factory. At the same time, the commercial department sends a copy of invoices to the apparels Store department.

The Store department receives two basic raw materials, and these are

- Fabrics

- Accessories

Apparels store procedures for receiving these two kinds of goods are as follows:-

1. The first apparels store Department receives the invoice from commercial.

2. The expected raw materials come to the Unloading Bay. Then the apparels store personnel match the invoices against the incoming raw materials and receive those.

3. They do the physical counting for detecting the proper quantity of goods.

4. apparels Store Department raises Goods Received Note (GRN). They are using software called ERP system, where they put all the operation details of the store.

Storing:

The received raw materials are then stores. They also do some repairing works for the ease of operation. They usually follow the different procedure for storing Fabrics and Accessories.

Fabrics Storing:

The steps taken to store fabrics are mentioned below.

1. The physical inventory of received goods and report.

2. Here they mark with three types of the sticker to indicate the condition of the received fabrics.

- Yellow color Sticker (♣) for the fabrics that are not inspected or just arrived.

- Green color sticker (♣ ) for ok or inspected fabrics.

- Red color sticker ( ♣) for rejected or defected fabrics.

3. Width measurement and Swatch cutting for Fabric Inspection Department.

4. Receive the inspection report and put it to cutting module system as per shade, shrinkage, rolls no length, and width.

5. The inspected fabrics are kept in the rack and a display board is placed there to display information about that particular fabric and fabric technology.

Accessories:

The processes of storing accessories are as follows:-

- All incoming accessories must pass through in the Quarantine area.

- Inventory of all accessories.

- Inspection of all accessories.

- Get all kind of approval from the buyer representative.

- Arrange those accessories style-wise in the rack.

- Make bundle as per cutting sheet.

Issuing:

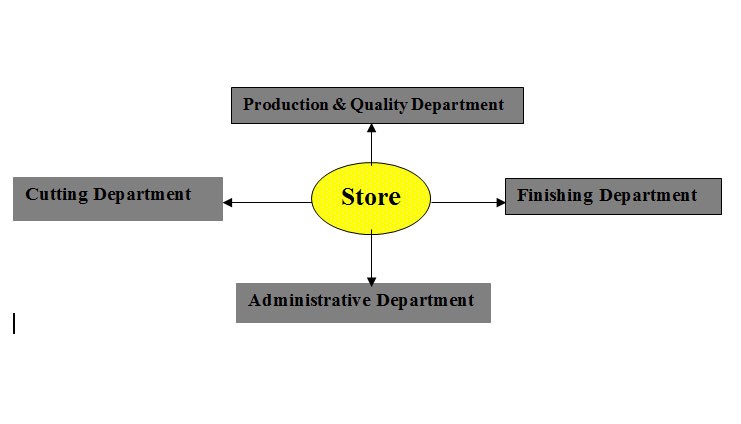

There are mainly four different sections where production related items are issued.

These can be shown as in the following diagram:-

Issuing of Fabrics:

- Cutting Department raises the requisition for fabrics from the cutting module system.

- Take the roll mentioned in the requisition and issue it.

- Update the entry for issue in the system.

Issuing of Accessories:

- Receive the bundled card from the production line.

- Check the accessories with the Trim Card and issue the required quantity.

- Receive the material requisition.

- Update the records in the system.

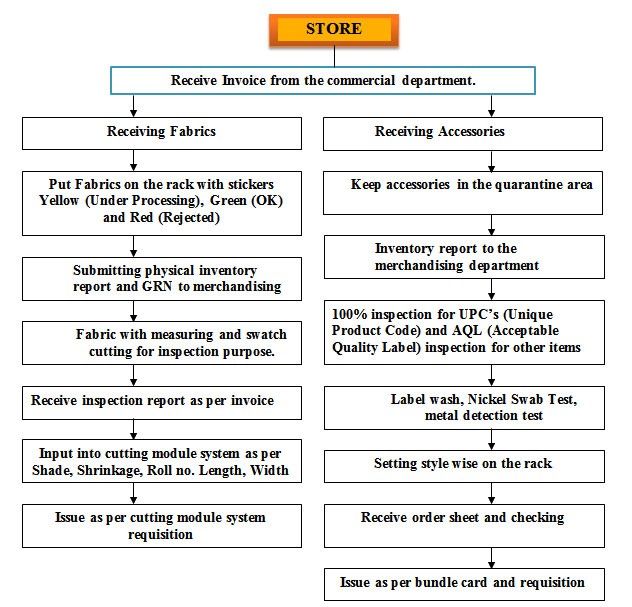

Total procedures of the apparels store can be shown as:-

(The process of Store activities (receive, stock, and the issue of fabrics and accessories).

Other Functions of the Store Area:

- Copy style wise Trim Card as per the instructions from Merchandising.

- Prepare accessories card for production line.

- Cut Zipper, Drawcord, Tape etc for production line as per instructed measurement.

- Ordering of stationeries and follow up with its uses.

The physical inventory of fabrics at the end of every week as it possesses the highest price. This system is known as ABC Analysis (80-20 concept). It secures the stock at stores near about fully as practically it’s difficult to check all items physically.