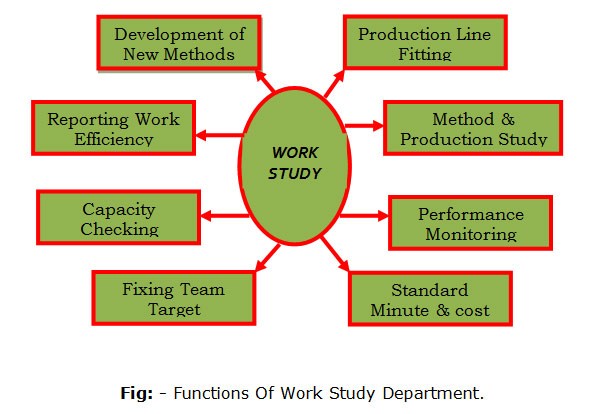

work study in industrial engineering department plays a very important role in the apparel industry. Production Effectiveness depends on this department. Objectives of work study in the industrial engineering department are maximizing production with minimum use of time as well as cost. This Department is based on the systematic examination of the methods of carrying on activities, so as to improve the effective use of resources.

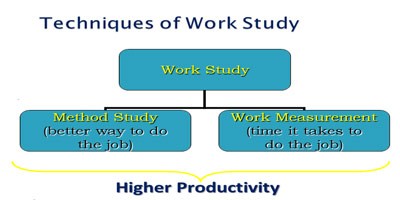

There are two types of study are followed:

- Method Study

- Time Study (Work Measurement)

Method Study is a systematic recording and critical examination of doing things in order to make improvements. There are many processes of achieving this objective-

- Use of Special Machines

- Use of Special Methods

- Appropriate Combination of Men & Machines

techniques and Objectives of work study in industrial engineering:

Table of Contents

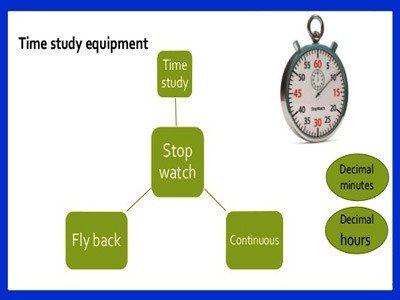

Time Study or Work Measurement is the application of techniques designed to establish a standard time for a qualified worker to carry out a task at a defined rate.

Work Study in industrial engineering usually works in two areas. Those areas are Method Study and Work Measurement. In the method study, the concerned staff usually has to look for an appropriate sequence of motions of the worker during the operation or manufacturing of the product on the floor so that they can measure the whole process to manage the same effect and thus cut down time-consuming to produce a garment.

Here problem has to be solved, no way to flee away. The common world standard process of performing the problem-solving process denotes the following rigidly:

Selection of the problem at the right time, recording the same with appropriate manner to understand by the expert or resource person, examining the whole deadlock or bottleneck with appropriate care and vigilance,

developing the new process or know-how to eradicate the bottleneck to allow smooth run of the production to ensure the efficiency in the end, defining the whole thing according to specified manner to get appropriate understanding from all concerned and at all the time, installing the same to all process alike prevailing in the floor irrespective of area, try to maintain this consistent procedure through appropriate staff so that this kind of problem won’t hamper the time of production during operation.

Work measurement includes the most important part of the technicality of this work study in industrial engineering department which holds SMV (Standard Minute Value) which denote how much time is essential to produce a full garment in what minutes. This norm denotes a time study, naturally, this is measured in two ways like estimation and synthesis.

SMV (Standard Minute Value) = BT (Basic Time of the operation) + MD (Machine Delay by the worker) +RA (Rest Allowance of the worker).

The target of the specific product is determined by this work study in the industrial engineering department also where target stands for,

Target = Working Minutes (x) Efficiency (x) Total number of Operators / SMV.

And Efficiency stands for,

Efficiency = SMV (x) Actual Output / Number of Operators (x) Working Minutes.

In this norms quality at the needlepoint is also ensured by SPC (Statistical Process Controlling).

In this system there are three-time garment checking is made like In-Line checking to ensure the cut panels are sewed or stitched properly and in right direction, End-Line Checking to ensure the whole body is good enough for final checking or to pack and the rest belong to Final checking or audit where concerned auditors ensure there is no appearance or major defect in all the garments .

through AQL standard that buyer has fixed for the final auditing internally which followed by Buyer QA intervention while they check on their own.

Most striking discovery to me was from today’s orientation was the information about the production efficiency of our operators in terms of needle time (needle downtime) and that was 1 and ½ hours out of 8 hours.

In short work study in industrial engineering put emphasis on the below workflow to ensure the production engineering favorable towards target achieving in the floor to meet the shipping window.

DIRECTING, CONTROLLING & CORRECTIVE ACTION

For this following are to do –

- Selecting problem areas

- Examine to find the reason

- Record keeping

- Defining Problem to the responsible person

- Installing the right procedure

- Maintaining the procedures

- Retaining the corrective action plan on track and monitor round the clock to avoid the further mistake.

- Archive maintaining for future reference.

Final Word :

Actually here in the work-study in the industrial engineering department ensures all sorts trims and line layout maintaining. Target also they fix out of the result got from pilot running. This acquired knowledge is infused in the line by the proper mechanism. Line balancing is one of the basic objectives of work study. This department ensures the costing process done by merchandiser more accurate and risk-free. This work study in the industrial engineering department which is really controlling the COC (Cost to the Company) in the source or in the beginning.